iPhone 17 Pro aluminum frame has been floating around the rumor mill for months, and I’ll be honest—I didn’t buy it at first. Apple just spent two flagship cycles flexing titanium. The look. The feel. The whole “premium” thing. Then a friend in product design poured coffee over my skepticism and said, “If the mission shifts to cooler chips and lighter pockets, aluminum’s the adult in the room.” I slept on that line, ran the numbers, and yeah—the case for aluminum isn’t just plausible. It’s compelling.

Quick anecdote before we go deep: last year I rode a red‑eye home from LA with a 4K edit churning on my phone. Ten minutes into color grading, the device pulled a classic hot‑pocket move and throttled. I shifted hands like a chef flipping pancakes. That late‑night misery is exactly why a redesigned thermal path—and a different mid‑frame—makes sense right now.

Setting the stage: from titanium fanfare to practical performance

Apple’s titanium run made real gains: lower fingerprint smudge, lighter than stainless steel, tougher face for micro‑scratches when properly finished. Competitors followed. But as silicon steps into the 3‑nm era and camera modules balloon in size, a phone’s frame isn’t just jewelry—it’s part of the cooling system and the weight budget. That’s where an iPhone 17 Pro aluminum frame enters the chat with two blunt questions: how fast can you spread heat, and how much mass can you cut without wrecking feel or durability?

We’ll mirror the debate in plain English, then nerd out on materials science. Two pillars carry the whole argument: (1) heat dissipation that supports sustained performance, and (2) thin‑and‑light ergonomics without clumsy compromises. If you only read one section, read those two. Everything else—cost, coatings, radio behavior, repairability—branches from them.

iPhone 17 Pro aluminum frame: Reason #1 — move heat farther, faster

Thermals decide everything from game FPS to charge speeds to whether you can record a 20‑minute 4K clip without sudden slowdowns. Metal choice shapes that thermal path. Aluminum’s headline advantage is simple: it conducts heat like a champ. Typical thermal conductivity values (room temp, common alloys) look roughly like this:

| Material | Thermal Conductivity (W/m·K) | Density (g/cm³) | Vibe for phones |

|---|---|---|---|

| Aluminum (6xxx/7xxx) | ~150–220 | ~2.7 | Great heat spreader, easy to machine/anodize |

| Titanium (Grade 5) | ~6–8 | ~4.4 | Strong, premium look, poor heat conduction |

| Stainless steel (304/316) | ~14–17 | ~7.9 | Very stiff, heavy, middling thermal path |

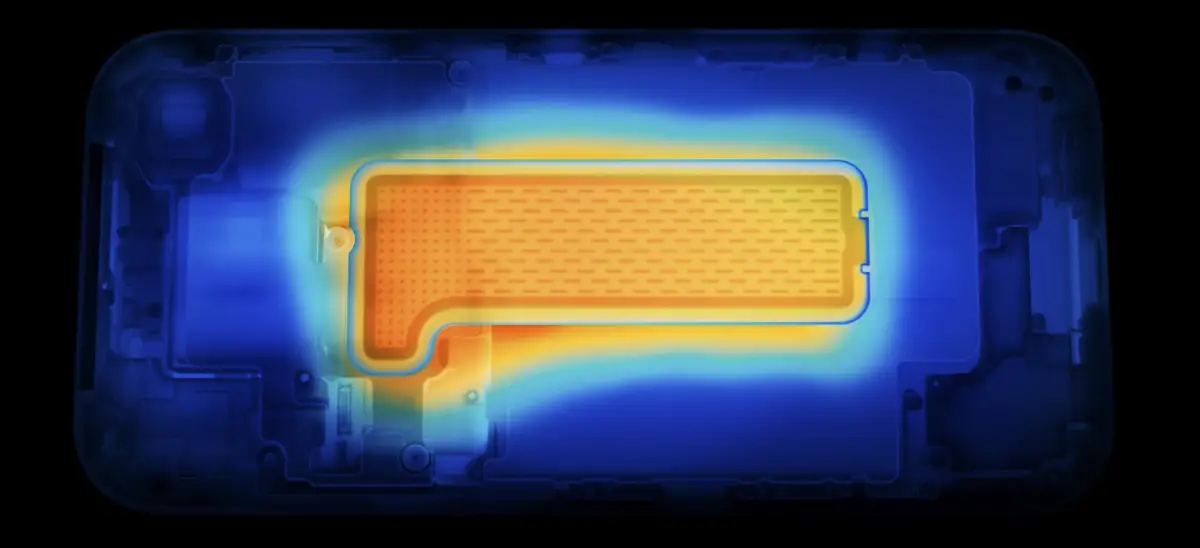

Those aren’t lab‑perfect numbers—they vary by exact alloy and temper—but they’re directionally right and they explain a lot. In real hardware, a hot SoC spreads into a graphite stack, into a vapor chamber (or heat pipe), then into the mid‑frame. If that mid‑frame is aluminum, the whole chassis acts like a big, gentle radiator. The surface warms evenly, throttling happens later, and your hands don’t hit that “too hot to charge” warning as easily. Put bluntly: an iPhone 17 Pro aluminum frame is a very efficient on‑device heatsink.

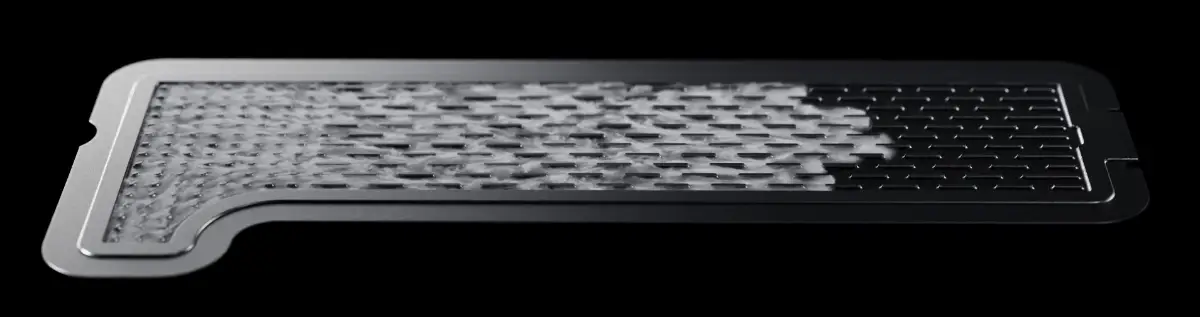

VC vapor chamber + aluminum = best friends

Vapor chambers (VC) absorb heat as liquid inside them vaporizes, then spread that energy across a larger area as the vapor condenses and returns via micro‑wick structures. They’re brilliant at flattening out hot spots. Pair a VC with a high‑conductivity frame and you get a two‑stage system: first the chamber smooths spikes, then the frame bleeds that energy into friendly, non‑painful surface warmth. The payoff is sustained GPU clocks during long gaming sessions, more stable 8K capture, and faster, safer wired/wireless charging windows. That’s the kind of real‑world upgrade you actually feel—and it begins at the frame.

Metal‑shell battery and the mid‑frame handshake

The buzz around a metal‑shelled battery points to a simple idea: make the pack part of the thermal network instead of a bystander. With a thin conductive shell tied into graphite sheets and the frame, heat moves laterally instead of spiking near the SoC. Aluminum makes that lateral move efficient. You wind up with fewer hot corners, healthier battery temps, and less throttling under charge. The mechanical upside is nice too: a stiffer, better‑protected pack that resists swelling and puncture.

Surface temp vs. internal temp: comfort math nobody talks about

Aluminum spreads heat fast, which means the peak temperature at any single hotspot drops. Your palm feels a warm plate, not a burning pixel. Internally, the SoC sits further below its throttle ceiling, so the scheduler doesn’t have to yank performance just to keep the die safe. If you’re into napkin math, Fourier’s law keeps popping up here:

// super-simplified heat flow across a slab Q = (k * A * ΔT) / L // higher k (aluminum) -> more Q for the same ΔT and thickness // result: heat leaves the hotspot faster, sustaining performanceLong story short: choose a frame with higher k (thermal conductivity), and everything down the line gets easier. In day‑to‑day life, that reads as cooler hands, steadier FPS, and fewer charging slowdowns. That’s a big vote for an iPhone 17 Pro aluminum frame.

iPhone 17 Pro aluminum frame: Reason #2 — thinner, lighter, nicer to hold

Weight distribution is ergonomics. Period. The frame is your biggest structural mass after the battery. Aluminum’s density is ~2.7 g/cm³; titanium is ~4.4; stainless is ~7.9. That’s why aluminum laptops feel impossibly light for their size and why aluminum phones can chase thin‑and‑light designs without turning into bendy bananas. A modern mid‑frame isn’t a solid bar; it’s ribs, bosses, and screw towers. Engineers shave grams with topology optimization—keep stiffness where loads concentrate and trim everywhere else. Aluminum shines in that game.

Stiffness, strength, and “pinky comfort”

Let’s separate stiffness from strength. Stiffness (Young’s modulus) tells you how much a material deflects under load. Aluminum’s modulus is ~69 GPa; titanium is ~110 GPa; stainless is ~200 GPa. So yes, aluminum is less stiff. That’s where design steps in: you can add flanges and closed‑section ribs that jump stiffness dramatically without adding much mass. The result is a phone that resists torsion when you twist it in your pocket or hit a corner drop. Meanwhile, the lower density trims overall weight so your “pinky shelf” doesn’t protest during doom‑scrolling. Practical win.

Camera bars, battery growth, and why grams matter more this year

Camera systems keep bulking up—bigger sensors, longer periscope stacks, heavier OIS assemblies. Batteries climb to satisfy AI compute and brighter displays. You can’t magic those grams away. What you can do is trim structural overhead so the total package lands in the sweet spot. An iPhone 17 Pro aluminum frame gives you that room. You re‑invest the saved grams into a bigger cell and a more serious cooling stack, but your hand still says, “Yep, this is comfy.”

Finishes and feel: anodized aluminum vs. PVD titanium

Titanium often leans on PVD or similar coatings for color and scratch behavior, while aluminum drinks up anodization like water. Anodizing forms a hard oxide layer that can be dyed deeply, resists fingerprints, and helps micro‑texture stick for grip. It also takes color more evenly over large batches, which keeps QA sane. On the hand, good anodized aluminum is silky without being slippery—think “less jewelry, more tool.” If you’ve ever loved the matte comfort of a unibody laptop, that’s the vibe an iPhone 17 Pro aluminum frame can deliver.

Durability trade‑offs you should expect

Titanium is tougher against certain scratches; aluminum can dent more easily on hard impacts. But the phone isn’t the frame alone. Glass stacks got better, corner geometries can be tuned for drop energy, and a slight curve or chamfer on rails spreads shock. Many users put cases on day one anyway. The real‑world delta often ends up smaller than spec sheets imply, especially with modern glass and smarter mid‑frame ribs. If you keep a thin case around—silicone or aramid—you’re unlikely to notice a durability downgrade, but you will feel the lighter carry all day.

Beyond the two big reasons: design details that ride along

Heat and weight lead the story, but they drag a whole entourage: antennas, machining, cost, sustainability, and repair. Let’s rapid‑fire through the rest—because they round out why an iPhone 17 Pro aluminum frame is a practical pivot.

Antenna performance and seam design

Metal frames need breaks for radios to breathe. Aluminum, like titanium or steel, is opaque to RF at phone wavelengths, so you sculpt dielectric windows and place PIFA/IFA elements behind them. Good news: aluminum machines clean antenna trenches, and its oxide layer is naturally insulating, which can reduce weird coupling with nearby parts. Expect tighter, cleaner seam lines if Apple continues the subtle laser‑etched approach seen on recent models.

Machining, forging, and yield

Aluminum is a machinist’s happy place. It cuts quickly, doesn’t work‑harden like stainless, and plays nicely with forging/extrusion to pre‑form complex shapes. Tooling lasts longer; cutters cry less. That often means higher yields and fewer cosmetic rejects—the silent killers of production timelines. If Apple wants the “Pro” look, they can run a fine glass‑bead blast followed by hard anodizing, then a chamfer cut for a little sparkle. It’s a recipe they know by heart.

Repair and sustainability

Lower mass means less shipping weight; cleaner machining means less waste; anodizing avoids some of the more exotic coating chemistries. On repair, an aluminum frame is usually friendlier for third‑party service: tapped threads hold well, seized screws are rarer than in titanium, and the oxide layer resists galvanic weirdness when you swap parts. The end result can be a longer‑lived device with saner repair bills.

Cost isn’t the headline—but it’s not nothing

Aluminum stock is cheaper than forged titanium billets, and cycle time on CNC drops too. That doesn’t mean a cheaper phone—Apple will always price to value—but it does free budget headroom for adding that larger VC, a beefier camera bar, or better display tech. If the rumor feels like “downgrade,” consider what the freed budget gets you elsewhere in the stack.

How an aluminum‑framed Pro could be tuned (a hypothetical build)

This is how I picture a balanced configuration if I were speccing an iPhone 17 Pro aluminum frame from scratch:

- Mid‑frame: 7xxx aluminum alloy with closed‑section ribs under the camera bar.

- Cooling: 35×67 mm copper vapor chamber tied to multilayer graphite pads and battery shell.

- Battery: Metal‑shelled pack bonded to the thermal stack with compliant pads for shock isolation.

- Display: Tandem OLED, anti‑glare micro‑etch, 1–120 Hz variable refresh.

- Finish: Hard anodized colorways (black, silver, blue, orange), subtle rail chamfer for grip comfort.

- Protection: Slightly raised bezel around camera to shield sapphire lenses; elastic corner bumpers inside the shell.

What this means for creators, gamers, and road warriors

If your phone is a camera: cooler frames mean longer 4K/8K capture without quality dips. If you’re gaming: stable GPU clocks and fewer thermal throttles. If you’re on the road: faster wireless charging before boarding because the system doesn’t trip thermal limits as fast. All of those wins start from something as unglamorous as material selection.

Answering the “Isn’t aluminum less premium?” side‑eye

Premium isn’t the alloy—it’s the experience. Apple made aluminum feel high‑end for a decade by acing machining, anodizing, and color. If the phone handles cooler, feels lighter, and still passes drop tests, I’m calling that premium. I’ve unboxed titanium phones that smudged and stainless phones that felt like pocket anchors. Meanwhile, unibody aluminum laptops still scream luxury. Framing matters; frames matter more.

Buyer’s guide: should you upgrade if the switch happens?

Short version: If your current phone overheats while filming or gaming—or if hand fatigue is a thing—watch the launch closely. If Apple couples the iPhone 17 Pro aluminum frame with a serious VC and larger battery, the practical gains could dwarf the badge swap. If your priority is scratch resistance without a case, titanium still wins on paper. That’s the honest trade‑off.

Two real‑world checkpoints at launch

- Sustained performance tests. Look for 15–20‑minute FPS traces in heavy games or long 8K video shoots. If frames stay smooth and charging speeds don’t fall off a cliff, the thermal path is working.

- Mass and balance. Don’t just check grams—hold it. A phone can be “light” but feel top‑heavy. Aluminum’s lower density should help the center of gravity sit closer to your grip.

For hardware nerds, here’s more to read

Cross‑check your instincts with a couple of excellent, high‑authority tech sources: teardown culture at iFixit and deep silicon coverage from AnandTech. Different angles, same goal—understand how material and thermal choices ripple through the whole device.

Related FoxDooTech reads (do‑follow, 2 picks)

- iPhone 17 Pro: 11 Epic Upgrades That Will Blow Your Mind

- TLC vs QLC SSD – 15 Brutally Honest Truths for Every PC Builder in 2025

FAQ: quick answers for the curious

Is aluminum really that much better at moving heat?

In broad strokes, yes. Common aluminum alloys conduct heat an order of magnitude better than titanium and many times better than stainless. That doesn’t make aluminum “the cooler metal” by itself—it just means your thermal stack can use the frame more effectively.

Will aluminum scratch more easily?

It’s more prone to cosmetic dings than titanium on hard impacts. With hard anodizing and a good case, the gap is smaller than online debates suggest. If you love going case‑less, expect tiny edge nicks over time—trade‑off for a lighter carry.

Could Apple keep titanium on another model?

Totally plausible. Apple likes to differentiate tiers. A Pro Plus/Ultra with titanium and a standard Pro with aluminum wouldn’t shock me. Different users, different priorities.

Does aluminum hurt 5G or Wi‑Fi?

No more than any other metal frame—antennas live behind plastic/glass windows either way. What matters is antenna placement and tuning, not the brand of metal.

What about corrosion?

Aluminum forms a protective oxide instantly in air; proper anodizing thickens it. Unless you’re beach‑soaking your phone daily, corrosion isn’t a practical worry.

Bottom line

If Apple really goes with an iPhone 17 Pro aluminum frame, it won’t be a downgrade—it’ll be a refocus. Cooler sustained performance and friendlier carry weight are everyday wins. Titanium still looks and sounds fancy, but materials are tools, not trophies. Use the right one for the job, and your phone simply feels better to live with.

FoxDoo Technology

FoxDoo Technology